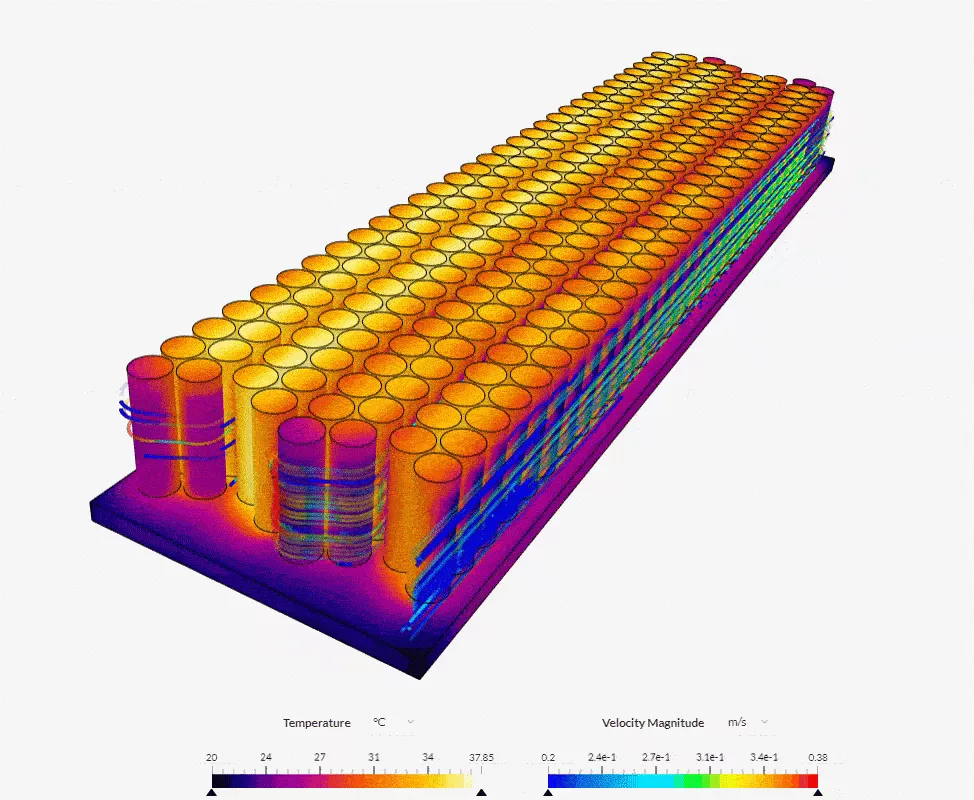

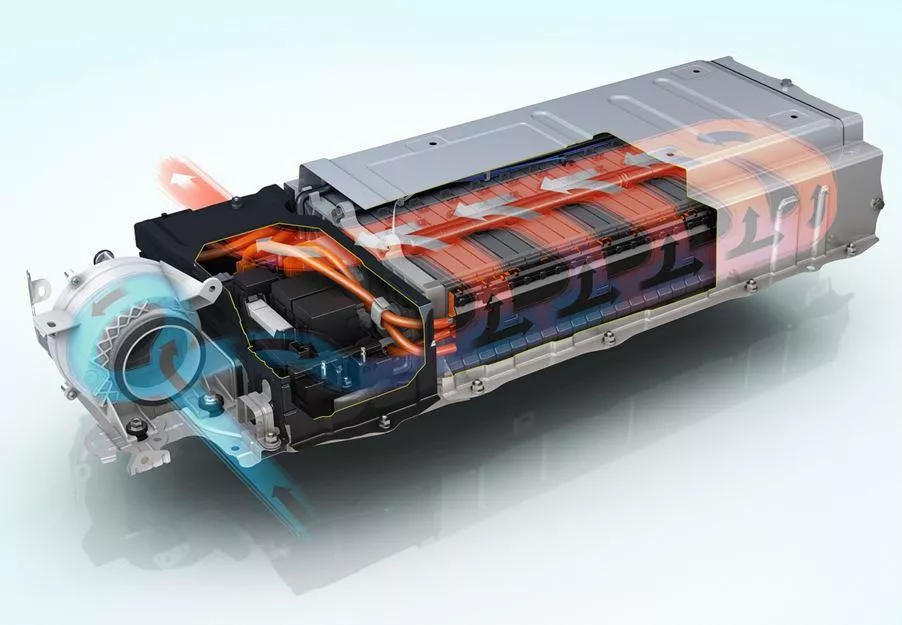

Thermal management of battery systems in electric vehicles is critical for preserving energy storage capacity, driving range, cell longevity and system safety. Lithium-Ion cells represent the cutting-edge technology in energy storage for electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs). Because of the current high costs and limited energy density, existing cells must be used to the fullest potential. By maximizing battery lifetime and facilitating the ideal operating conditions, electric vehicle range and lifetime can be maximized.

Lithium-Ion cells are inherently subject to aging not only over time, but also due to operating conditions influences including their state of charge (SOC), current, and extreme temperatures. These factors have varied effects on the multitude of cell chemistries in use today, but temperature has a universal influence on the performance degradation of nearly all Lithium-Ion chemistries. The high cell currents mandated by consumer requirements such as rapid charging during performance driving result in high heat losses in the cells. Not only the average or maximum temperature in a cell influences aging, but also the temperature gradient across a cell or module. Premature aging of a single cell can degrade the performance of a module noticeably.

The goal of a battery thermal management system (BTMS) is to increase the lifetime of Lithium-Ion cells and thus the battery system by regulating the temperature level and distribution. A BTMS is especially necessary when the cells are susceptible to high rates of charging (e.g., rapid charging or regenerative breaking) and discharging (e.g., high performance vehicles, plug-in hybrids), and when the vehicle is operated in very high or low ambient temperatures.

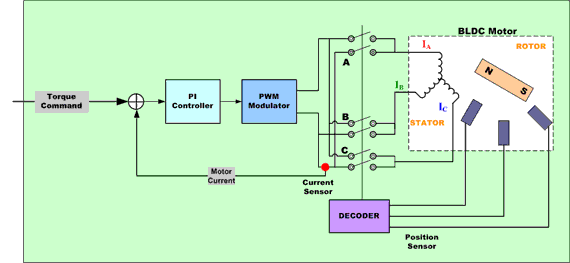

Modeling and analysis of motor and motor controller in MATLAB /SIMULINK

Modeling and analysis of motors and motor controllers in MATLAB is an essential task for designing and optimizing motor control systems. In this process, a MATLAB model of the motor is developed, and then a control system is designed using this model.