Analysis of DFMEA

and PFMEA use for

enhanced co-development of product and

production

Purpose: In recent years, innovation, product complexity and customisation, and continuous and rapid technological change have presented businesses with challenges. The ability of a business to quickly adapt to changes through product innovation and efficiency is critical to its market success. Utilizing various tools in the New Product Development (NPD) process, such as Design and Process Failure Mode and Effects Analysis (DFMEA and PFMEA), risk analysis may result in success. This study means to recognize how the reconciliation among DFMEA and

PFMEA could upgrade the co-advancement of item and creation to defeat the

challenges in the NPD. Three research questions have been formulated to address the purpose: 1) Is there a connection between DFMEA and PFMEA in the literature, and if so, how? 2) From a practical standpoint, what are the main obstacles and opportunities associated with integrating DFMEA and PFMEA? 3) How can the integration of DFMEA and PFMEA be enhanced for improved product and production co-development?

The research took an inductive approach, and qualitative methods like document reviews, interviews, and workshops were used to collect the data. A case study and a literature review were the strategies chosen. To begin, a literature review was conducted to determine the connection between DFMEA and PFMEA as well as possible integration strategies. After that, recorded interviews and documentation from two businesses were examined for practical information.

Lastly, in conjunction with the responsible individuals from the two companies that were examined, two workshops were held to investigate additional connections between DFMEA and PFMEA.

Results and Discussion: Three useful approaches that connected DFMEA and PFMEA were found in the literature. Two distinct scenarios were portrayed following the review of the company documentation, two workshops, and the recorded interviews. The businesses use different templates and have slightly different procedures. As a result, when comparing the two businesses, a SWOT analysis was helpful in identifying their integration challenges and opportunities.

The three approaches, as well as the comparison of the businesses and other reflections, contributed to the advancement of knowledge and enhanced the operations of the businesses.

Time constraints were the primary limitation of the study. Due to the lack of time for further investigation in this thesis, this research could take a number of different paths. In fact, the goal was to find a way to test in the businesses and get results from the test. Eventually, the outcomes are idea for additional exploration and strategies for incorporating DFMEA and PFMEA.

Keywords include risk assessment, integrated FMEA, production development, and failure mode and effects analysis.

I would like to express my gratitude to everyone who helped me through the Master’s program, particularly during the thesis’ final months. First and foremost, I would like to express my gratitude to Marisol, my supervisor from the School of Engineering at Jönköping University, for her guidance and assistance throughout the thesis process. In addition, I would like to express my gratitude to Fredrik Elgh for introducing me to the IDEAL Project and providing me with the opportunity to attend various workshops with the participating businesses.

In addition, I might want to thank the two organizations for their accessibility and backing

that permitted me to lead the contextual investigation. I was able to accomplish the goal of this study thanks to their expertise and insights.

Last but not least, I would like to express my deepest gratitude to my loved ones, who, despite the distance, have always been there for me to support me and assist me in overcoming any challenges I have faced over the past two years.

Global trends like product customization and complexity, shorter delivery and production times, continuous and rapid technological change, and sustainable development pose a challenge to manufacturing businesses today.

According to Johansson and Säfsten (2015), the main obstacles to a product’s production and efficiency are, in fact, the team’s ability to deal with the product’s complexity, the integration of product and production development, and the dispersion of communication among team members. As a result, a company will outperform its rivals if it is able to quickly respond to shifts in the market through product and service innovation and effectiveness.

1 Product Realisation

The majority of published research envisions the manufacturing procedure as a broader process that encompasses more than just the fabrication and assembly procedures. Understanding the requirements of the customer is the first step, followed by thinking about and designing the product, delivery, customer service, and reverse logistics (Balakrishnan et al., 1999; 2010, Bellgran and Säfsten; Magrab and other, 2009).

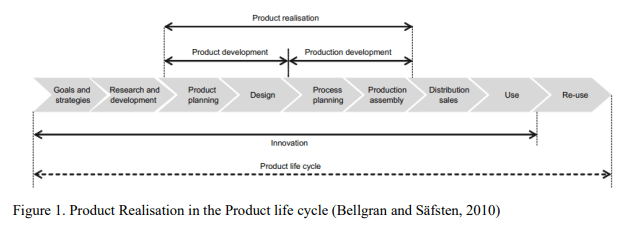

Product Realization is a part of the Product Life Cycle and includes both Product and Production Development, which are divided into product planning and design and process planning and production assembly, respectively, as shown in Figure 1.

As per Bellgran and Säfsten (2010), the item and the creation cycle must

be co-foster to guarantee a fruitful item acknowledgment. Although there are certain issues that arise as a result of the coordination and cooperation of these activities, it is essential. Nitty gritty data with respect to the item is expected for the effective advancement of

the creation framework. Similarly, information about the production development, workplace design, work environment, or material supply system may improve the product’s manufacturability during the design phase, shorten the product realization lead time, and speed up delivery to the customer (Bellgran and Säfsten, 2010).

In addition, a long-term strategy that incorporates product and production co-development moves toward production that is more cost-effective, sustainable, and less wasteful, thereby increasing the reuse of process, knowledge, components, and resources (Gedell et al.,

2011). The Production Preparation Process (3P), a lean methodology that encourages the integration of product and process design through the collaboration of cross-functional teams and the rapid testing of ideas and lean concepts, is an example of this strategy (Ramakrishnan and Testani, 2011).

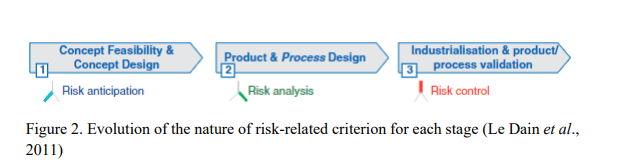

Over the past few years, the New Product Development (NPD) process has been defined in numerous ways. However, team members from various roles collaborate at various stages in each of these definitions (Johansson and Säfsten, 2015; Le Dain and others, 2011; 2009, Kim and Kim; 2006, Fliess and Becker; Swink, 1999). For instance, Le Dain et al. 2011) characterize the NPD for the most part in three unique stages: product and process design, product/process validation, concept feasibility, and finally industrialization All things considered, Fliess and Becker (2006) distinguish four phases in view of

their review: initial stage, during which the customer evaluates and selects suppliers; concept stage; process engineering stage; and product introduction stage.

Since NPD teams are cross-functional, their members come from a variety of functional areas and contribute their knowledge and experience to the project. 2015, Johansson and Säfsten; 2009, Kim and Kim; Swink, 1999). Additionally, the NPD process involves suppliers and customers, among other external stakeholders (Le Dain et al., 2011; (2006) (Fliess and Becker).

According to Levandowski, Raudberget, and Johannesson (2014), the early stages of product development are frequently characterized by a high degree of design freedom and uncertainty due to the lack of design knowledge. Various factors related to the product’s configuration present challenges throughout the design process. Long order horizons make product mix uncertainties worse, product complexity and variations make solution management more difficult, and customers frequently require one-of-a-kind products (Christensen and Brunoe, 2018). All of these factors contribute to the product’s characteristics being determined over time. To increase their competitiveness in the market, businesses must therefore consider the needs of their customers and be mindful of their NPD, as being innovative is no longer sufficient. Lin and team,

2015). If NPD activities are unsuccessful and risks are not identified, particularly in the.

Challenges in the NPD

Today, in the context of Industry 4.0, where technology is always getting better, market needs are changing quickly, and more data is being collected, the decision-making process is one of the main challenges in NPD (de Andrade et al., 2022). To be able to use historical records and retrieve old models and patterns, the most important aspect is the quality of the collected data in terms of integrity, credibility, clarity, and accuracy of their parameters (Jamshed et al., 2019). To ensure accuracy, clarity, relevance, and objectivity, heterogeneity in the interpretation and collection process of the information must be avoided in order to achieve data quality (Leite et al., 2018).

When developing a new product, Hermann, Pentek, and Otto (2016) identify four design principles that may assist in identifying obstacles and avoiding misinterpretations and divergences: i) Interdependence: standardization, collaboration among humans, machines, and humans and machines, and increased cyber security; ( ii) Information openness: data analytics must be available to all employees and provide information in real time; ( iii) decisions made decentralizedly; and (iv) assistance with technology: both virtual and actual help because of the expanded intricacy of creation.

The distribution to the customer is impacted by additional manufacturing challenges, which place additional constraints on the engineering domain when developing the production process. These deterrents can be conquered utilizing systems that help

engineers changing over the client prerequisites in specialized necessities and explicit

customizations (Ferguson, Olewnik and Cormier, 2014). In addition, Khadilkar and Stauffner (1996) found a way to design a new product using old design information to improve product development, reduce uncertainty, and meet new customer needs.

Shenhar (2001) asserts that all of these challenges can be overcome, including a preventative step in which organizations classify the project for NPD and make significant decisions based on the type of project, such as selecting the project leader, team members, necessary technological knowledge, risk assessment, product value, and organizational capabilities, among other things. For instance, knowing how to assess risk in a project is crucial for avoiding the causes and consequences of potential failures. Each organization’s definition of acceptable and unacceptable risk differs: It is affected by available financial and economic resources, technological capabilities and limitations, and team members’ level of experience. Bahrami and other, 2012) Le Dain and colleagues 2011) as depicted in Figure 2 identify three evolutions of the nature of risk-related criteria for each of the aforementioned stages.

After that, they define various tools needed to evaluate efficiency in the product and process performance area, such as Failure Mode and Effect Analysis (FMEA), which is a risk analysis of the product and process, Design for Manufacturing and Assembly (DFMA), which is a tool for product-process integration, and so on. Le Dain and others, 2011). The first, FMEA, is broken down into three main methods.

System-FMEA, which examines the product before its integration into a system

from an analytical point of view

• Design-FMEA, which develops the design of the product and searches for failures in the design

• Process-FMEA, which examines failures in the production process

According to Breiing and Kunz (2002), the three methods are carried out independently, by different teams, at various points during the product’s realization. System-, design-, and process FMEA implementation results in overall improvements to the component design, a decrease in mishap-related failures, an increase in product quality and productivity, and a reduction in assembly rejections and time losses caused by inadequate machining.

In general, the FMEA application is regarded as a useful tool for reducing the risk of failure modes in both the NPD process and the manufacturing process.

Even though some failure modes may not be related to NPD, it is less likely that failures reach customers if risks are identified early in the NPD process.

FMEA diminishes disappointment modes that are not perceived and made due. Thus,

the organization succeeds and makes due in the market thanks to the minimization of expenses

furthermore, time-to-advertise and improved quality (Moreira et al., 2021).

IDEAL Project

As part of the research project IDEAL – Integrated product and production platforms supporting agile and demand-driven industrial product realization, the School of Engineering (JTH) collaborated with two Swedish businesses to coordinate the presented study, which is a final project work thesis in Production System. Six businesses representing a variety of industries and a number of researchers from Jönköping University’s School of Engineering are all involved in the IDEAL Project. The primary purpose of the case studies that have been created in these sectors is to provide an answer to the fundamental research question of how integrated product and production platforms can support agile and demand-industrial product realization. Four subprojects are included: Production platform co-development, digitalization and automation of integrated Introduction 5 product and production platforms, and boundary objects supporting integrated platform development are all examples of changeable product platforms. All of the subprojects add to the body of knowledge and support for research on how manufacturing companies can compete in a market with a lot of variation and constant change.

The Design and Process Failure Mode and Effects Analysis (DFMEA/PFMEA) will be the focus of this in-depth investigation into ways to enhance product and production co-development. As case studies, this study will be carried out in the aforementioned businesses.

Purpose and research questions

In light of the above-mentioned problem statement, the purpose of this study is to add to the existing body of knowledge and enhance the current working procedures, methods, and implementation regarding the integration of DFMEA and PFMEA in a NPD setting to enhance product and production process co-development.

The purpose is met by looking into and discussing the critical events, procedures, and methods that were used to implement DFMEA and PFMEA in the two Swedish businesses, as well as in the case studies that can be found in the literature. The goal is to improve and combine these tools in order to open up opportunities for collaboration.

The following research questions have been formulated to address the objective:

- Is there a connection between DFMEA and PFMEA in the literature, and if so, how?

- From a practical standpoint, which are the most significant difficulties and opportunities associated with integrating DFMEA and PFMEA?

Delimitations

The study will focus on the research of new ideas and solutions regarding the improvement of DFMEA and PFMEA, and then one of these solutions is intended to be selected

for the company as a test. It is not feasible to address every challenge that could arise

within the integration of the product and process development, for this reason, the study

focuses on the co-development of product and production through the integration of

DFMEA and PFMEA. Moreover, it will be difficult to evaluate the implementation of

the proposed solutions in the long term due to the short time and prioritization of projects in the companies.

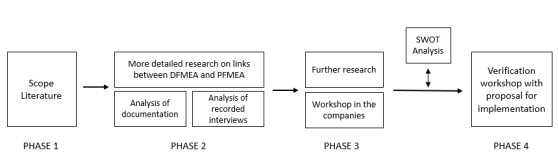

Research phases

A literature review and a case study based on two different Swedish businesses were used to outline the research. The first goal of the study is to test and implement a new methodology in the two companies studied by looking for ideas in the literature. A while later, information assortment was done in the organization utilizing

subjective techniques, for example, exploring documentation, meetings, and studio.

Last but not least, businesses are asked to evaluate the degree to which it would be practical to implement the more suitable approach for enhancing the co-development of Design and Process FMEA. As a result, the method can be described as a deductive method. According to Saunders et al., this method is described in the literature as a process in which the research is developed beginning with reading academic literature to gain a general overview and to guide the study toward the formation of a theory and its demonstration through robust analysis. 2016). Figure 3 depicts the various stages of the research process: