Introduction:

Testing & Homologation Rules for EV Battery (2023):

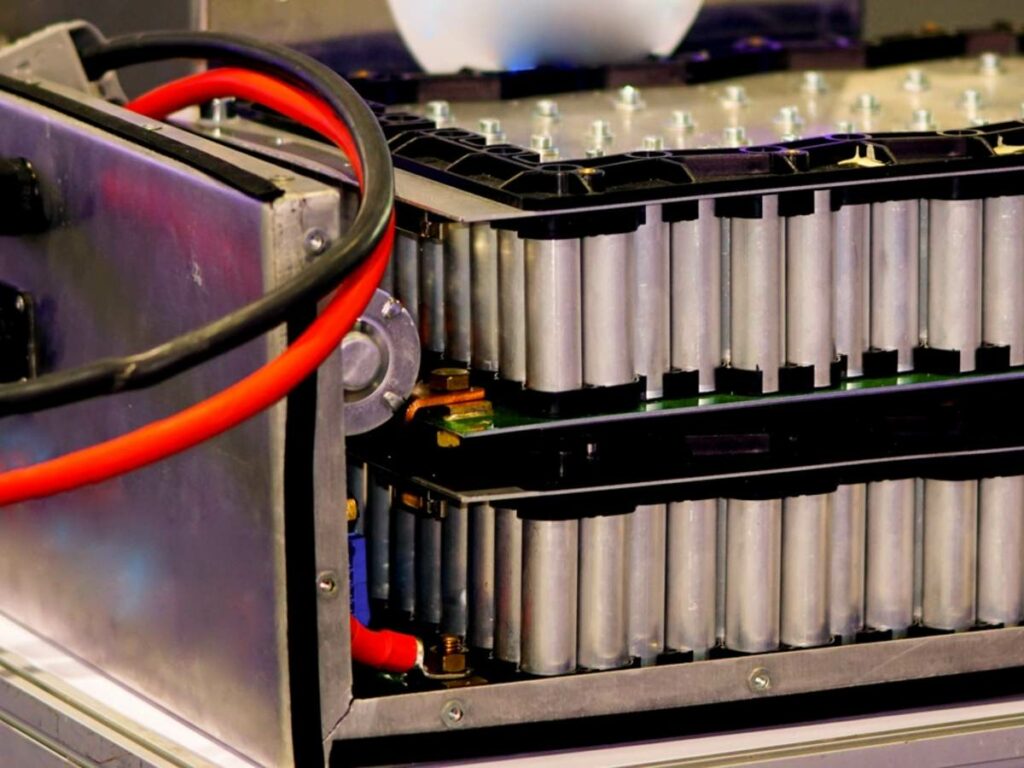

As electric vehicles (EVs) continue to gain popularity and become an integral part of the transportation landscape, ensuring the safety and performance of their batteries becomes paramount. To regulate the quality and reliability of EV batteries, various testing and homologation rules have been put in place. In this blog post, we will explore the Testing & Homologation Rules for EV Battery (2023), shedding light on the important aspects that manufacturers and consumers should be aware of. Let’s delve into the details. Importance of Testing & Homologation for EV Batteries

Importance of Testing & Homologation Rules for EV Battery (2023)

Testing & Homologation Rules for EV Battery ensuring the safety, efficiency, and reliability of EV batteries is crucial for the widespread adoption of electric vehicles. Testing and homologation processes help verify the compliance of EV batteries with stringent safety and performance standards. These processes provide assurance to manufacturers, regulators, and consumers that the batteries meet the required specifications and can operate safely under various conditions.

International Standards for EV Battery Testing:

Several international organizations have developed standards for EV battery testing. Notable ones include the International Electrotechnical Commission (IEC), Society of Automotive Engineers (SAE), and the United Nations Economic Commission for Europe (UNECE). These standards cover aspects such as electrical performance, environmental testing, thermal management, safety requirements, and more.

Key Testing Parameters for EV Batteries:

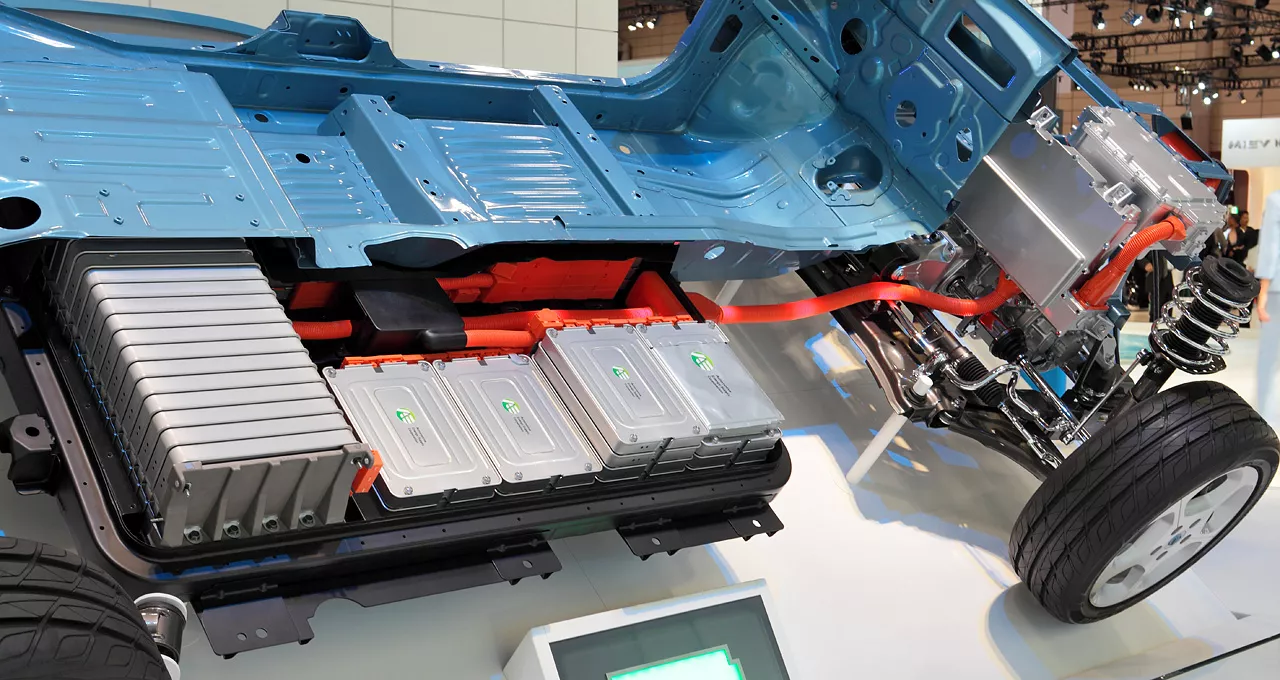

EV battery testing involves a range of parameters to evaluate its performance and safety. Some essential testing parameters include energy capacity, charging efficiency, voltage stability, thermal management, cycle life, durability, and resistance to environmental factors like temperature, humidity, and vibrations. These tests ensure that the battery can withstand real-world conditions and perform reliably over its intended lifespan.

Homologation Process for EV Batteries:

The homologation process for EV batteries involves a series of tests and documentation to validate the compliance of batteries with applicable regulations and standards. It typically includes tests related to electrical safety, mechanical integrity, electromagnetic compatibility (EMC), and environmental impact. Manufacturers must submit the necessary documentation and test reports to obtain the required certifications.

Regulatory Bodies and Certifications for EV Batteries:

In India, the Automotive Research Association of India (ARAI) and the International Centre for Automotive Technology (ICAT) are the primary regulatory bodies responsible for testing and certifying EV batteries. They ensure that the batteries meet the safety, performance, and quality requirements as per the Indian regulations. Certifications such as ARAI certification and ICAT approval are essential for market entry and consumer confidence.

Challenges and Future Developments:

As the EV industry continues to evolve, testing and homologation processes for EV batteries face ongoing challenges. These include the need for standardized testing protocols, the development of advanced testing facilities, and keeping pace with the rapid advancements in battery technology. Regulatory bodies and industry stakeholders are actively working towards addressing these challenges to ensure the continuous improvement of testing and homologation procedures.

Conclusion:

Testing and homologation rules for EV batteries play a crucial role in ensuring the safety, performance, and reliability of electric vehicles. By adhering to international standards, manufacturers can produce batteries that meet stringent quality requirements. Regulatory bodies like ARAI and ICAT in India effectively oversee the homologation process, Testing & Homologation Rules for EV Battery providing necessary certifications. As the EV industry progresses, ongoing advancements in testing protocols and facilities will further enhance the quality and safety of EV batteries, supporting the widespread adoption of electric vehicles.