Additive Manufacturing & Rapid Prototyping Certification Course

About Additive Manufacturing & Rapid Prototyping Course

DIYguru has prepared a one-of-a-kind fundamental certification course on Electric Vehicle with 30 Days duration for beginners in the EV Industry. This course can be taken by anyone with basic knowledge of Physics and Chemistry as first milestone in your approach to explore wide varity of career and future scopes in EV Industry

DIY Project

Every DIYguru course comes with a Do It Yourself project which you can do and learn by doing at your comfort. Our goal is to make sure you are able to implement your learning in real-world scenerio.

Internship

Every candidate after successful completion of the project submit a pitch presentation video, explaining his/her project-oriented achievements and results, which enables them to do one month of internship with us.

Certification

We are the only platform in india approved by National Education Alliance for Technology - NEAT, AICTE, Ministry of Education, Govt. of India along with Automotive Skills Development Council.

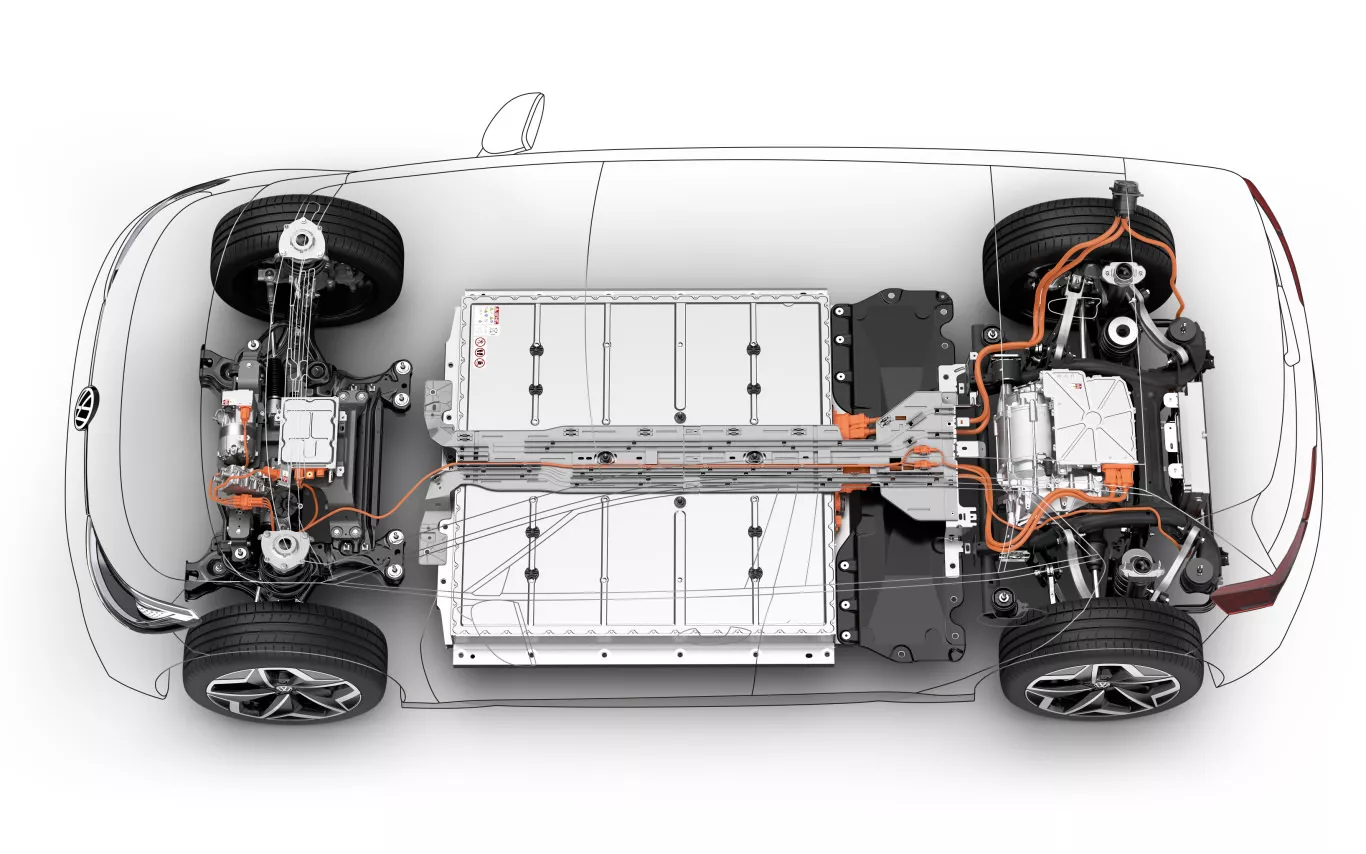

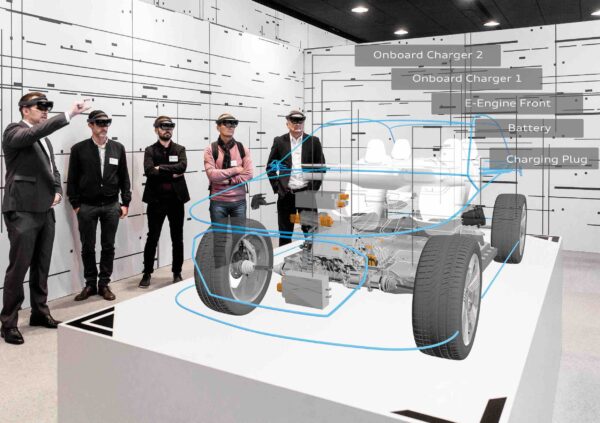

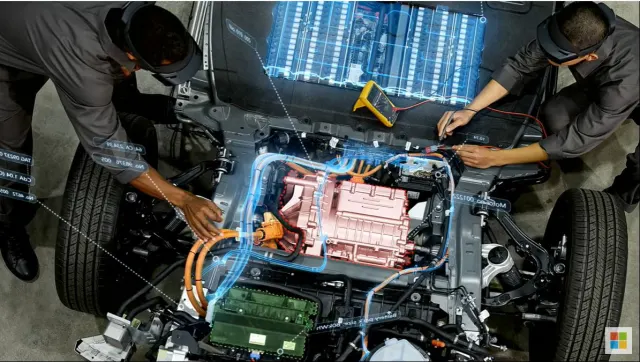

Understand the EV architecture

Aquire deep knowledge in EV System architecture with thorough understanding of components in Electric Vehicles.

Benefits of learning from DIYguru

Proactive Program Support

Dedicated Program Manager to solve your queriesDual Certificate from Govt. of India

Avail certification from ASDC & AICTE, Ministry of Education, Govt. of IndiaLearn anytime anywhere

Learn through online videos by world class faculties.

DIYguru alumni are working at various roles in

Who is this program for?

- B.E./B.Tech. students and fresh engineering graduates who want to launch their careers in the EV Industry

- Ideal for candidates from engineering disciplines like electrical, electronics, mechanical and automobile engineering

- Learners with 0-3 years of experience who are looking to transition into a career in EV industry.

- Min 60% in 10th. 12th and graduation

Specialized roles one can apply for after doing this course

This programme is tailored to help you improve your engineering skills as a student, recent graduate, or working professional with following expertise.

- Performance Engineers

- Lead Engineers

- Integration Engineers

- Powertrain Engineers

- Vehicle Engineers

- Vehicle Validation Engineer

- System Validation Engineers

- Sub-systems Engineers

- Chief Engineers / Assistant Chief Engineer

- Assistant Engineers

- Powertrain Chief Engineers

- Functional Engineer

- Performance Integration Engineers

- Attributes Engineers

- EV Operators

- Vehicle Assembling

- EV Entrepreneurs

- EV Technical Consultants

- Value Engineering Teams From OEMs

- Technical Experts

- EV Product Developer

- Cost Engineering Teams

- EV Research Scholars

- Retrofitters

What you’ll learn – Syllabus

Covering all the way from Motor Design to BMS Manufacturing and EV Industry set up for OEMS’s. DIYguru vast range of services in E-Mobility is unmatched.

1. Electric Car Evolution

A lookback into the history and evolution of electric vehicles starting from 1884 to the future of mobility until 2030.

Lesson 1: Introduction to Electric Vehicle Industry

Lesson 2: The end and begining of Electric Vehicle Era.

Lesson 3: Role of EV in energy transition.

2. xEV Components Explained

Understand the components used in Electric Vehicles and their use case with examples.

Lesson 1: Types of Motors and their use case in EVs

Lesson 2: Types of Batteries and their use case in EVs.

Lesson 3: Charging Infrastructure components and Technology.

Lesson 4: EV Safety protocols and associated components explanation.

3. Design Process of xEV

Understand the flowchart for designing an Electric Vehicle.

Lesson 1: Chassis Design Parameters & Raw material selection

Lesson 2: Design of Powertrain System

Lesson 3: Design of Battery & Battery Manangement Systems.

Lesson 4: Design of Motor & Motor Controllers

4. Converters / Inverters & Controllers

Main devices of power electronics devices required in an electric vehicle. How converters, inverters and controllers interact with other sub-systems in EVs.

Lesson 1: Working Principles of Rectifiers, Power Converters & Inverters.

Lesson 2: Working principles of Controllers and Sensors.

Lesson 3: Functioning of Power Electronics misc. accessories and Electrical Machines in Electric Vehicles

5. xEV Homologation & Charging Infrastructure

Understand the process of testing and certification for adherence to technical standards is known as type approval.

Lesson 1: Evolution of Testing standards and norms in India

Lesson 2: FAME Policy ( Faster Adoption and Manufacturing of (Hybrid &) Electric Vehicles in India) Explained

Lesson 3: AIS (Automotive Industry Standards) for type approval explained.

Lesson 4: Charging Infratructure, Types of Charging Standards explained.

Project included in this course

Get the full curriculum

Download the full curriculum with topics and units explanation attached with the set of DIY Projects in this course.

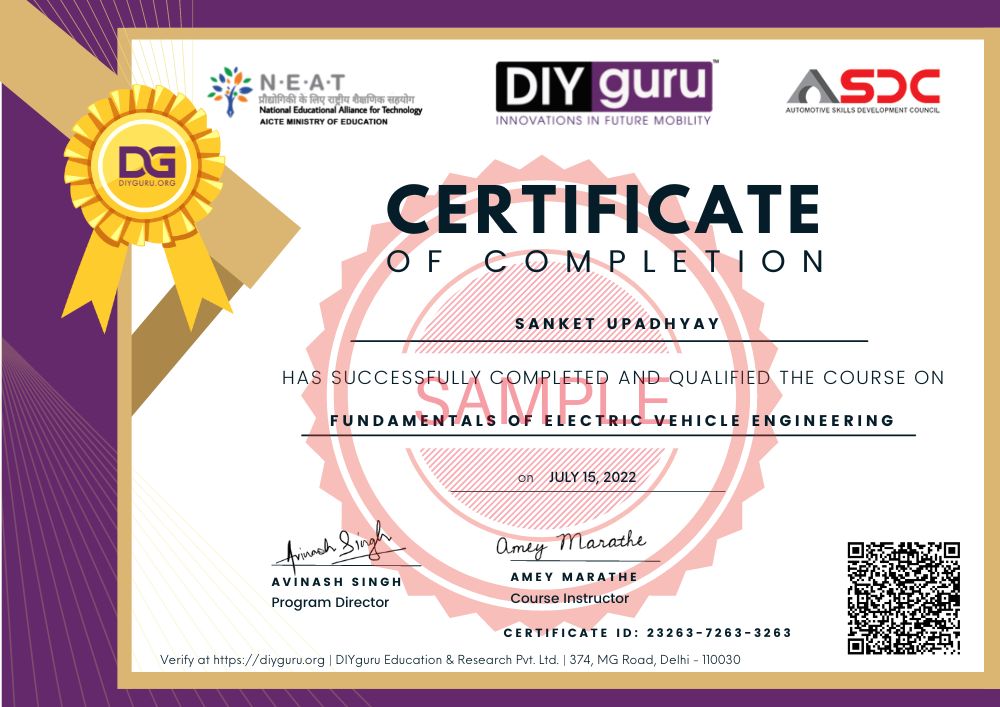

Sample certificate

Electric Vehicle Global Verified Certificate

Certified by ASDC, Automotive Skills Development Council & NEAT, AICTE, All India Council for Technical Education, Govt. of India

Learner Stories

Hear #PowerAhead stories of career growth from our learners

“DIYguru has helped us a lot in improvising the concepts of electric vehicle design & engineering for our experienced and fresh employees. The trainers are of high quality and knowledgeable in terms of delivering the contents and making things understandable. We look forward to having a continuous relationship.”

| R Shashi Kumar, Head HR – Robert Bosch Engineering

Learners love DIYguru

Here’s what some of our 40,000+ satisfied learners have to say about studying with DIYguru Team.

"Very informative course, high quality in terms of quizzes and assignments, liked the project at the end of the course. Oh, and great support. Can recommend this one to my friends and colleaugues. Being the very first player in EV industry, DIYguru has been crucial to the EV ecosystem development in india"

"I have known DIYguru since 2013 when the first version Autosports india was launched and in last 6-8 years the platform has emerged as the leading maker's learning platform in india. Form me the team behind DIYguru has been the best support all through the journey after Bachelors till my master's"

"Some of the best customer service I've ever seen. Great platform for mechanical and electrical engineers to learn EV!"

"This is truly a 5 star experience for youngsters in india! keen to learn about EV Technology"

"The platform has helped me personally to build my career in renewable energy in Canada. Hope to see DIYguru in Canada soon. Five stars!"

"liked the course with wide range of calculations in EV, all tutors are very supportive."

"Automotive design with incredible knowledgebase in terms of support from Baja Tutor community of DIYguru is wonderful experience. Documentation on the web is also good. "

"Amazing content and great support from DIYguru community"

Recent Placements

Avg. Salary Package > 3.5L

66% Alumni Career Transitions

73+ Hiring Partners

50% Average Salary Hike

Featured In - Media Spotlight

Awards and Recognitions

Frequently Asked Questions

Specialization and Individual Courses can be done online mode only. To attend offline class you need to enroll for either Nanodegree or PG Diploma program.

DIYguru centers are located in Delhi, Pune, Bangalore, Nepal, Bangladesh, Malaysia and Germany. To see the address, check Contact section of website.

Yes, all the individual courses, Nanodegree Programs, Specialization Programs and PG Programs are govt. approved.

NEAT (National Education Alliance for Technology) - AICTE, Ministry of Education, Govt. of India & ASDC, Automotive Skills Development Council.

Min. 12th pass can undergo this course. Students and Working Professionals with ITI, Diploma, BE / B.Tech or equivalent in domains such as Automotive, Mechanical, Electrical, Electronics can pursue this course.

Three Month, however in case you are unable to finish the course in three month, you can request for an extension here - Contact.

Two minor Project + One Major Project (Mandatory)

No. For Practical Hands on Training, you need to enroll for either Nanodegree or PG Diploma Program.

Yes, DIY KITs are available for this course, To avail it simply click on enroll button and it will shop you the option of purchasing course specific DIY KIT.

Admission fee for this course is 20000 INR / 250 USD

During checkout, you will get the option of paying in EMI

You will be given 6 month access to this course, to get lifetime access, you need to pay 10,000 INR / 120 USD.

Admission process for individual courses is direct online, there is no requirement of any screening test. However for Nanodegree and PG programs, you need to appear for test before taking admission.

You can avail project based internship for this course upon successfull completion.

Stepwise procedure for the course enrollment with a 4-week internship project

- Step 1: Apply for the internship-based learning-based course and fill the application form.

- Step 2: Pay the necessary fee to enroll in the program.

- Step 3: The technical team of DIYuru will check your entered data, and will share the confirmation of acceptance as you will be shortlisted in the next 24 hours.

- Step 4: Once you are enrolled in the course, start working on the course videos, and given assignments, and complete the course at your own learning pace! With this, you shall receive the ‘course completion’ certificate.

Project-based Internship process

- Step 5: If you have applied for the ‘internship-based learning’, then the team DIYguru Support shall connect with you to share the date of the ‘live course certification examination!’. This examination will enable you to understand your current expertise and will allow us to define the best possible project for you! Students will get a minimum of 4 weeks for the examination preparation.

- Step 6: Once you clear the examination, the DIYguru technical mentors will contact you to enroll you in the ‘live project’. Since students will work on a live project, students will get enough time to prepare themselves before the internship project begins.

- Step 7:

Since it is an ‘internship’ based project, the students will be encouraged to work through the assigned project in teams and will be allowed to achieve the results on their own, with mentorship support from DIYguru! Allowing you to gain the actual skills as an ‘intern’! Enrolled students will get a minimum of 4-6 weeks to work and submit their project reports.

- DIYguru shall also allow you to work in groups or as an individual. However, at the end of the internship, each student shall submit a project report with all the results achieved, for evaluation by the DIYguru technical team.

- Every candidate after successful completion of the internship project shall also submit a pitch presentation video, explaining his/her project-oriented achievements and results, so that the participants can work on their communication and presentational skills simultaneously. With this, you shall receive the ‘Project-based internship’ certificate (along with evaluation score), and an ‘achievement badge’ to validate that you have successfully cleared the ‘certification examination’ (shareable on LinkedIn and other platforms).

The internship after the completion of course is unpaid.

Placement assistance in terms of access to the Job portal will be provided, and you will be added to the weekly job update newsletter section to receive opportunities available in our partner companies.

Still have questions? Get in touch

Related Blogs

DIYguru Enhances EV Education with Upgraded PG Certification Programme

DIYguru announces the upgrade of its EV Nanodegree to a Post Graduate Certification Programme, offering existing Nanodegree students an enhanced curriculum and Post Graduate certification at no extra cost. Enrollment is open now.

Top 10 Beautiful Electric Vehicle Scooters for Girls in India 2024

Revolutionizing Sustainable Future: DIYguru’s Visionary 77th Independence Day Speech on E-Mobility

Get in touch to learn more about how you can make the best of your talent

Spend less time worrying about job availability, and more time growing your knowledge. Join DIYguru Program today.

If you’re a current student, please get in touch through the DIYguru dashboard to ask about more details of this Program.

Please note, eligibility for this course is reserved to students who have done related projects and have relevant profiles matching with the pre-requisite of this course.

The DIYguru team hold the right to cancel your admisssion into the program without any explanation via email if found unsuitable and unfit.

Our 7-day money-back guarantee starts from the moment of signup and runs through the free week. Cancellations between days 7 and 30 will get a prorated refund.

Fees for the program is charged only when the admission is approved.