Types of Sensors

There are numerous varieties of sensors. We at Variohm provide a comprehensive selection of sensors for use in both business and industry.

Sensors are utilized in almost every industry for applications that we encounter on a daily basis, as well as more specialized and industrial ones.

A sensor is used to take a measurement, the measurement will be processed, and the result of the process, an output, will be given. Sensors can also be found in our cars, buses, trains, trams, restaurants, food processing factories, and production lines, among other places. After that, something will alter or move as a result of the output. The temperature sensor in a thermostat is a straightforward illustration. The boiler shuts down as a result of the temperature measurement being processed once it reaches the desired temperature, which is continuously monitored by the temperature sensor.

Types of Sensors

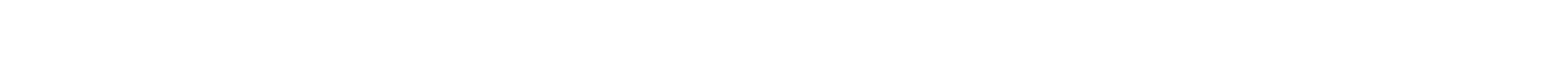

There are numerous types of sensors, the most common of which are:

- Position Sensors

- Pressure Sensors

- Temperature Sensors

- Force Sensors

- Vibration Sensors

- Piezo Sensors

- Fluid Property Sensors

- Humidity Sensors

- Strain gauges

- Photo Optic Sensors

- Flow and Level Switches

All of these categories can be further broken down into subcategories. For instance, there are the following kinds of position sensors:

- Contacting

- Non-contacting

- Rotary

- Linear

And these types of sensors can be split even further, within non-contacting you have the following types of sensors;

- Hall effect

- Capacitive

- Eddy Current

- Ultrasonic

- Laser

- Proximity

It is evident that the number of sensors in the modern world is so vast that a single blog post could not cover all of them by splitting them into one category, Position Sensors. However, here is a summary of the various sensors that Variohm can provide:

Types of Sensors – Position Sensors

There are numerous varieties of position sensors, as previously mentioned; direct, turning, reaching, non-reaching and utilize a wide range of innovations. An object’s position or displacement can be measured and tracked with position sensors.

Over the course of more than four decades, we have developed our own line of position sensors, which we have added to the extensive collection provided by our partners and suppliers. Our own assortment includes:

Sensors for linear positions

Rotary Position Sensor

Further reading on Position Sensors

Types of Sensors – Pressure Sensors

Typically, pressure sensors fall into one of two categories: Pressure switches and pressure transducers The primary distinction lies in the fact that pressure switches are triggered by a predetermined limit and pressure transducers provide precise feedback on real-time pressure. The mechanism in pressure switches and pressure transducers uses the equation Pressure = force divided by area to measure pressure.

A wide range of industries make use of pressure sensors, which can measure the pressure of gases, liquids, or solids. Because the pressure they measure is directly related to the water’s level, underwater pressure transducers are also known as level meters.

Pressure can be measured in Bar or PSI and can be gauge, differential, absolute, or vacuum.

We also have our own line of; many of our trusted suppliers supply us with our pressure sensors.

Pressure Transducers – EPT range

Types of Sensors – Load Cells and Force Sensors

There are many different sizes and shapes of load cells. Weight is the most common force that can be measured with them. Load cells are utilized in a wide range of scales; industrial scales, truck scales, hopper scales, bathroom scales, counting scales, and everything in between

The majority of load cells monitor force based on the strain gauge’s degree of distortion using internal strain gauges.

Our dependable suppliers provide our load cells. and are visible on our website.

More information about load cells

Types of Sensors – Temperature Sensors

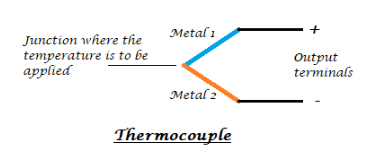

One more part that can distinguish the variety in temperature is a thermocouple. A junction is created by joining two distinct metals together during its construction. It works on the premise that a varying potential exists between the terminals of two distinct metals when their junctions are heated or subjected to high temperatures. As a result, the amount of temperature change can be measured using the varying potential.

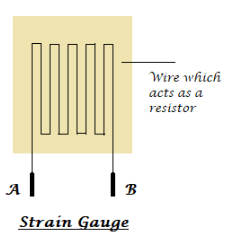

Strain Gauge (Pressure/Force Sensor):

When a load is applied, pressure is measured with a strain gauge. We are aware that the resistance is inversely proportional to the wire’s cross-sectional area (R=l/a) and is directly proportional to the length of the wire. Here, the load can be measured using the same method. A wire is arranged in a zigzag pattern on a flexible board, as depicted in the image below. As a result, the overall length and cross-sectional area of the wire change when pressure is applied to that particular board. The wire’s resistance changes as a result. The Wheatstone bridge can be used to determine the extremely small (few ohms) resistance that was obtained as a result. The remaining values remain unchanged when the strain gauge is positioned in one of the bridge’s four arms. As a result, pressure can be determined by varying the bridge’s current and resistance in response to pressure applied to it.

Strain gauges are mostly used to figure out how much pressure an airplane wing can withstand, but they can also be used to figure out how many cars can go on a certain road, etc.

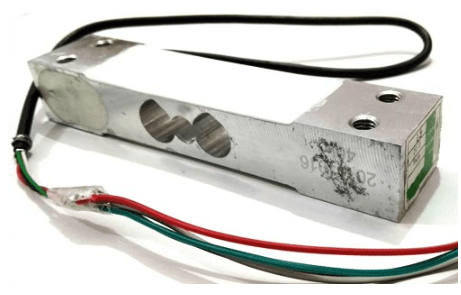

Load Cell (Weight Sensor):

Similar to strain gauges, load cells measure a physical quantity like force and produce electrical signals as their output. At the point when some pressure is applied on the heap cell it structure differs causing the adjustment of opposition lastly, its worth can be adjusted utilizing a Wheatstone span. This project shows how to use a load cell to measure weight.

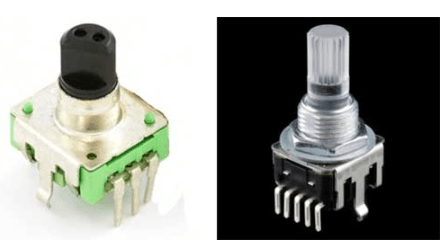

Encoder:

An encoder can also be used to detect the change in position. It has a round rotatable plate like design with explicit in the middle of between to such an extent that when the IR beams or light beams go through it a couple of light beams get identified. In addition, these rays are encoded into digital binary data that represents the precise position.

Hall Sensor:

It is clear from the name that this sensor uses the Hall Effect. A potential difference is created across a given conductor when a magnetic field is brought close to the current-carrying conductor (perpendicular to the direction of the electric field). A Hall sensor is used to detect the magnetic field and provides voltage output thanks to this property. The Hall sensor can only detect one magnet pole, so care must be taken.

Flex Sensor:

A FLEX sensor is a transducer whose resistance shifts in response to being bent or changed in shape. A FLEX sensor is the length of a finger, or 2.2 inches. In the figure, it is depicted. Simply put, when the sensor terminal is bent, its resistance rises. If we are unable to read them, this change in resistance will be of no use. We will use a voltage divider circuit so that we can derive the change in resistance as a voltage change using the controller at hand, which can only read voltage changes. Find out how to use Flex Sensor here.

Microphone (Sound Sensor):

Every mobile phone or smartphone has a microphone. It can convert audio signals into electrical signals with a small voltage (mV). There are many different kinds of microphones, such as carbon microphones, condenser microphones, and so on. Capacitance, piezoelectric effect, and resistance are just a few of the properties that each type of microphone uses. Let’s look at how a crystal microphone that uses the piezoelectric effect works. The bimorph crystal used generates proportional alternating voltage when subjected to pressure or vibration. A drive pin connects a diaphragm to the crystal, causing it to move to and fro when the sound signal hits it. This movement changes the position of the drive pin, which causes vibrations in the crystal and generates an alternating voltage for the applied sound signal. An amplifier receives the obtained voltage to boost the signal’s overall strength. Here are a few microphone-based circuits.

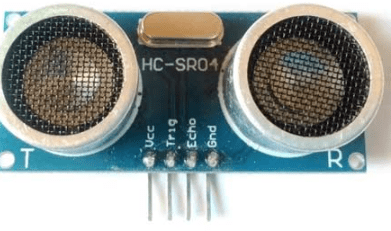

Ultrasonic sensor:

The frequency range is all that is meant by the term “ultrasonic.” Even when it is turned on, we are unable to detect these sound signals because its range is greater than the audible range (>20 kHz). Those ultrasonic waves can be detected by specific speakers and receivers. This ultrasonic sensor is used to calculate the distance between the target and the ultrasonic transmitter and to measure the target’s velocity.

The ultrasonic sensor HC-SR04 has an accuracy of 3 millimeters and can be used to measure distances between 2 cm and 400 cm. Examine the operation of this module. The HCSR04 module produces a sound vibration in ultrasonic reach when we make the ‘Trigger’ pin high for around 10us which will send a 8 cycle sonic burst at the speed of sound and subsequent to striking the article, it will be gotten by the Reverberation pin. Contingent upon the time taken by sound vibration to get back, it gives the fitting heartbeat yield. Based on how long it takes for the ultrasonic wave to return to the sensor, we can determine the object’s distance.

The ultrasonic sensor can be put to use in a lot of different ways. We can use it to avoid obstacles for moving robots, automated cars, etc. The RADAR system will employ the same strategy for spotting intruder aircraft and missiles. The ultrasonic sounds can be detected by a mosquito. As a result, ultrasonic waves can be used to repel mosquitoes.

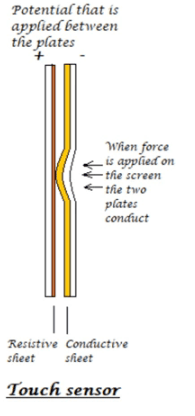

Touch Sensor:

We can say that almost everyone in this generation has a smartphone with a widescreen and a touch-sensitive screen. Therefore, let’s examine how this touchscreen operates. There are basically two types of touch sensors: capacitive-based touch screens and resistive-based touch screens. Let’s talk briefly about how these sensors work.

The resistive touchscreen consists of a resistive sheet at the screen’s base and a conductive sheet beneath it. The sheets are separated by an air gap and are subjected to a small voltage. The software detects the location and takes the appropriate action when we press or touch the screen, causing the conductive sheet to touch the resistive sheet at that point.

In contrast, capacitive touch relies on the body’s electrostatic charge. The all-electric field has already charged the screen. Electrostatic charge that circulates throughout our bodies creates a closed circuit when we touch the screen. In addition, the location and the action to be taken are selected by software. We can see that capacitive touch screen won’t work when wear hand gloves since there will not be conduction between the finger(s) and the screen.

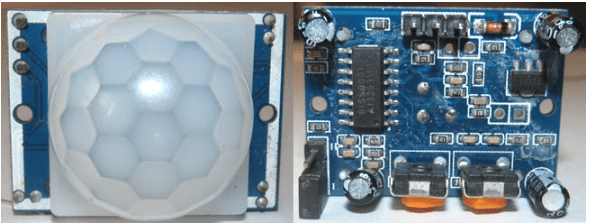

PIR sensor:

Passive Infrared is the acronym for a PIR sensor. These are used to track the movement of people, animals, or other objects. We are aware that reflection is a property of infrared rays. The properties of an infrared ray change when it hits an object, and this received signal determines the motion of the object or living thing, depending on the temperature of the target. The properties of the reflected infrared rays are able to precisely distinguish the objects, even if the shape of the object changes. The entire functioning PIR sensor can be found here.

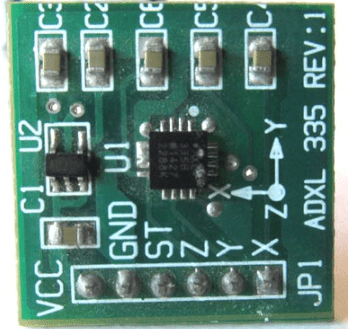

Accelerometer (Tilt Sensor):

An accelerometer can detect a device’s tilt or movement in a specific direction. Based on the acceleration force brought about by the earth’s gravity, it works. Its tiny internal parts are so sensitive that they will react to a small shift in position from the outside. When tilted, a piezoelectric crystal causes a disturbance in the crystal and generates potential that determines the precise X, Y, and Z positions.

Gas sensor:

In industrial applications, gas leak detection relies heavily on gas sensors. In the end, an incredible disaster occurs if such a device is not installed in these areas. Depending on the kind of gas that needs to be detected, these gas sensors are broken down into a variety of categories. Examine the operation of this sensor. Under a metal sheet there exists a detecting component which is associated with the terminals where a current is applied to it. The chemical reaction that occurs when the gas particles hit the sensing element changes the elements’ resistance and the current that flows through it, enabling the gas to be detected.

Finally, we can say that sensors are used not only to automate devices and simplify our work by measuring physical quantities, but also to assist living things in times of disaster.